Generac Industrial Power Generator Paralleling

Simplified Generator Paralleling with Generac MPS

What is Generator Paralleling?

Generac has taken the complexity out of paralleling total power generators with our Modular Power Systems (MPS). MPS is a transformational technology that eliminates the expense and space requirements required with traditional paralleling solutions. In the past, you had to purchase pricey third-party switchgear. Then you had to find suppliers and electricians to set-up the system and make it work when you needed it. Generac provides integrated paralleling, simplifying the entire system.

The Redundancy for Emergency

Instead of relying on a single diesel generator during power emergencies, more electrical engineers are recognizing the benefit of paralleled generators. Gaseous generators can provide the same amount of power as a larger genset, while adding redundancy, flexibility, expandability, and reliability.

Helicopters represent a marvel of modern engineering. They hover, maneuver, accelerate, and land—all without wings, jets, or a runway. Most helicopters contain numerous mechanical redundancies and failsafe systems to keep them airborne in case of emergency. However, many also have one critical design flaw. The main rotor retaining nut, notoriously known as the “Jesus Pin,” stands as the lone helicopter component without a redundant backup. If the nut fails during flight, the propeller disconnects, and gravity transforms what was formerly a helicopter into Newton’s Apple.

Industrial Jesus Pins

Many modern industrial facilities rely on a “Jesus Pin” of a different sort—a stand-alone back-up generator. Traditionally, a high-kW diesel generator provided many advantages in case of a power shortage emergency. Fuel is relatively inexpensive (although diesel fuel has to be replaced periodically to prevent spoilage). One machine, depending on the size, can usually produce enough power to maintain operations as usual.

They also have one major drawback—when a power emergency occurs, that’s a lot of faith to place in one generator.

Redundancy & Flexibility & Flexibility & Redundancy

Instead of relying on one solitary diesel generator to switch on during power emergencies, more industrial facility designers recognize the benefit of installing systems of smaller, paralleled generators instead. These systems, usually natural-gas fueled, can provide the same amount of power as a larger generator, with exponentially more redundancy, flexibility, expandability, and reliability.

Reasons to Run a Generator System in Parallel

By creating a system of paralleled generators, one or more individual generator can fail and the system as a whole will still produce power, albeit a lesser amount. (Compare this to the all or nothing precariousness of lone diesel unit.) Natural gas, while not quite as cheap as diesel, will still flow even if highway systems clog. It also has the added benefit of not spoiling over time.

Additionally, parallel generator systems contain room for expansion. If you need to add a new wing to your facility or install new power-sapping machinery, you can link additional generators into the system to support it, instead of being forced to replace one capital-heavy unit.

Emergencies like power outages (or helicopter malfunctions) occur very rarely. But if/when they do…how much faith are you willing to place in your Jesus Pin? Generac Industrial Power has over 50 years of experience in configuring parallel generator systems.

MPS Advantages

How Does Generator Paralleling Work?

Our integrated MPS offers many benefits as opposed to the traditional single genset configuration including:

Redundancy: in most applications, the loads that require the highest degree of reliability are only a percentage of the generator’s total capacity. We provide N+1, N+2, and more, offering up to 99.999% reliability.

Reduced Space Requirements: using smaller kW generators offers greater weight distribution, making rooftop installations more feasible. These generators are also shorter and more compact so locating them in parking garages becomes a possibility.

Serviceability: a single unit can be taken out of service for maintenance or repair while other units remain available should an outage occur.

Flexibility: gensets can be added to a current system depending on growth. This allows owners to make a smaller initial investment and scale accordingly based on increased power demands.

Fuel Redundancy: while some applications require diesel generators to meet on-site fuel requirements, our diesel generators can be paralleled with our natural gas or bi-fuel generators for significantly expanded runtimes.

Fully Tested: our in-house factory test lab ensures unsurpassed peace of mind because if our generators pass our tests, they’ll pass your tests, too.

The costs to specify and install two lower kW paralleled versus one larger kW are quite similar. This makes choosing Generac’s MPS a smart decision for all types of and sizes of facilities or businesses.

Disruptive Gemini™ Units

For many applications, space is at a premium. To help meet these needs, Generac introduced the first and only compact paralleled total power generator solution that houses two 500 kW generators within a single enclosure. The Gemini™ MPS Twin Pack provides 1000 kW of power in a footprint that is 20% smaller compared to single large genset. In addition, up to seven Gemini gensets can be paralleled without additional switchgear, for a total output of up to 7000 kW on a single bus.

Rest Easy … Our Integrated Controller Approach Assures No Systemic Failures

Our generators are designed to work with no functioning communications or load share lines. This means that when active communications go down, MPS generators are still fully capable of automatic starting, paralleling, and load balancing without manual starting. No other system supplies this level of automatic backup, making Generac’s standard MPS configuration the most reliable system available today.

The Generac Integrated Control concept also reduces installation hassles and eliminates complicated and custom PLC programming - saving you time and simplifying system set up.

The Integrated Generator Control concept is the basis of the modular power system category. It includes everything you need to control paralleling – synchronizer, speed governor biasing, automatic voltage regulator biasing, communications, load sharing, metering, protective relaying, operator interface and even custom logic capabilities. Everything that until now required several controllers to provide. This integrated controller platform is extremely flexible and allows you to take advantage of:

- Expandable I/O modules – analog and discrete

- Advanced communication capabilities – onsite and via web

- Support of low and medium voltage paralleling

- Custom event and alarm capabilities to site specific needs - motorized louvers, remote fuel tanks, day tanks, remote breakers, etc.

- Custom logic capabilities providing maximum application flexibility

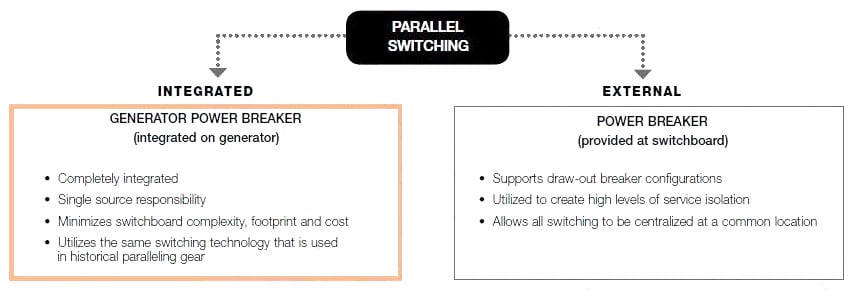

The parallel switching can be located internally to the generator or integrated at the switchboard.

Strategies for MPS Paralleling

Since our MPS solution utilizes an integrated paralleling design concept, this allows for location flexibility in the switching and load sequencing.

Two Paralleling Switching Options

The parallel switching can be located internally to the generator or integrated at the switchboard.

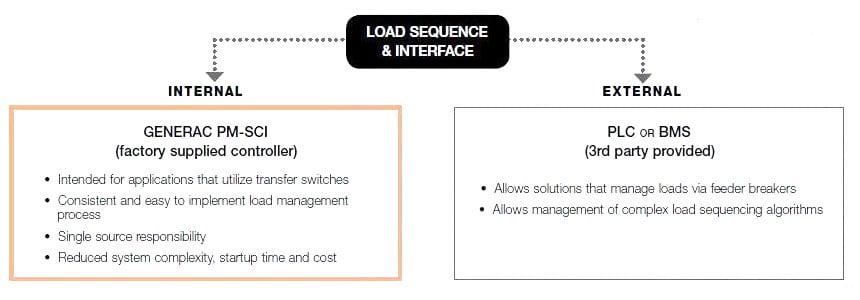

Two Load Sequencing and Interface Options

Load sequencing and interface can be integrated within the Generac PM-SCi, or externally provided within a custom PLC or BMS solution.

Generac’s MPS Removes the Complexity and Fear from Medium Voltage Applications

Medium voltage applications are often specified with a medium voltage alternator and ANSI C37.20.2 gear. However, many medium voltage systems can benefit from our integrated paralleling concept.

By paralleling on the low voltage side and feeding one or multiple transformers, many system advantages are gained:

- Facility staff are typically more comfortable interacting with low voltage generators.

- Low voltage equipment is much easier and quicker to source.

- This approach supports the integration of low voltage rental equipment when needed.

- No medium voltage paralleling switchgear sections are required, resulting in a smaller footprint and significant cost savings.

Medium-voltage—the trouble-free way—that’s Generac.

Why Choose Generac?

With more nearly six decades of experience, Generac can provide the paralleling solutions you need. Our wide variety of sizes, fuel choices, and configurations allow facility managers, engineers, and contractors to make the selections that provide the best value. As your power needs grow, our inventive MPS grows with you.

We also have a nationwide network of Industrial Power Distributors to offer support during every part of the process from sizing to fuel selection to specifications to design and installation.

Relax. Generac has made paralleling simple, smart, and less complex.